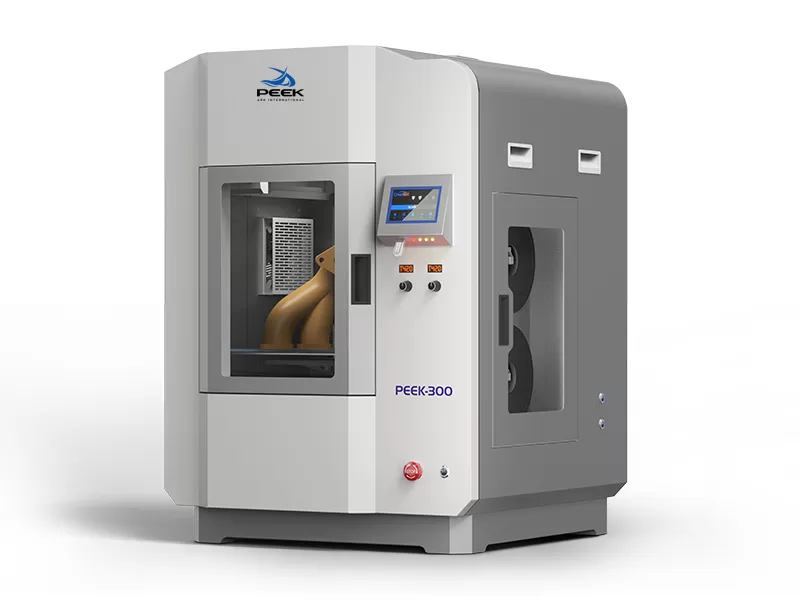

Direct Annealing System (DAS), the world's first and extraordinary technology by. Annealing process is instant controllable during printing. It aims to provide best quality parts in one time without warping and cracking printing of big size functional materials. (The technology is patent protected and available by only) TECHNICAL DATA Printing Build Volume 300*300*400 mm Print Resolution 0.04 mm-0.4 mm Filament Diameter 1.75 mm Number of Nozzles Dual Extruder Print Speed 10-150 mm/s Nozzle Diameter 0.4 mm (0.3~1.0 mm optional) Filament Compatibility Engineering Plastics: PLA, TPU, PC, ABS, PA6, PETG, PVDF, TPUHigh temperature Material: PPSU, PEI (ULTEM), PA12, PSU, PPS, PA-CF, POM, PPUltra-performance material: Medical grade PEEK, PEEK, PEKK, CF-PEEK (Carbon fiber), GF-PEEK (glass fiber), etc. Software Software Bundle Creatware, Simplify3D, Cura, Slice3r Operating Systems Win7/8/10, MacOS Print File Type STL, OBJ, AMF, Gcode Special Function Outage Restored Save data when power is off Filament Detection Pause printing when filament run out Direct AnnealingSystem (DAS) Annealing process is instant controllable during printing. It aims to provide best quality parts in one time without warping and crackingprinting of big size functional materials. Heat insulation Triple heat insulation Emergency stop switch Support emergency stop High temperatureaccessories High temperature resistance motors, linear rails, belts and circuits toensure long time high temperature printing. Temperature Nozzle Max. Temperature 500 ℃ Chamber Temperature 120 ℃ Platform Max. Temperature 200 ℃ Direct Annealing Temperature 0~400 ℃ Mechanical Cooling Air pump cooling & water cooling Platform PCB aluminum + PEEK print board Positioning Precision X Y axis 0.01mm, Z axis 0.0025mm Extruder Directly Drive Machine Construction Fully enclosed hot chamber Bed Leveling Manually/Automatic Electrical Input Power 200~240 V, 120A Max. Power 3 000 W Screen 4.3'' full color touch screen, multi-language Print Method USB Connectivity/USB Disk Size & Weight Machine Size 650*600*750 mm G.W 100 kg Packing Size 820*720*1080mm N.W 135 kg Specs Comparison With Other Brands PEEK-300 Stratasys F370 Intamsys Funmat Pro410 Apium M220 Place of origin China USA China Germany Build Volume(mm) 300*300*400 355*254*355 305*305*406 170*170*130 Max Nozzletemperature 500 ℃ 300℃ 450℃ 540 ℃ Max Chamber temperature 120℃ 90℃ 90℃ Max hot bed temperature 200 °C - 160 °C - Temperature around the part is controlled 0-400 ℃ None None 0-200 ℃ Min layer resolution 0.04 mm 0.013 mm 0.05 mm 0.1 mm Number of extruder 2 2 2 1 Build platform Carbon fiber sheet - Ceramic Glass Medical grade material Materials PEKK, PEEK, medical PEEK, Carbon-PEEK, ULTEM, PEI, PPSU, PA/CF, PC, PA Alloys, PA6, PA12, ABS, Carbon Fiber, Nylon, ASA, PETG, ESD-Safe, HIPS, TPU, PLA, PVA, TPU 65A,ETC. PLA, ABS, ASA, PC-ABS, TPU 92A PEEK,PEI,PPSU, PA/CF, PC, PC Alloys, PA, ABS, Carbon Fiber-Filled, Metal-Filled, Fiberglass-Filled, Nylon, ASA, PETG, ESD-Safe, HIPS, TPU, PLA, PVA, ETC. Medical PEEK Machine size 650*600*750 964*711*1626 720*680*1470 850*685*675 Weight 120 kg 227 kg (with cabinet) 200 kg (with cabinet) 66 kg